Design

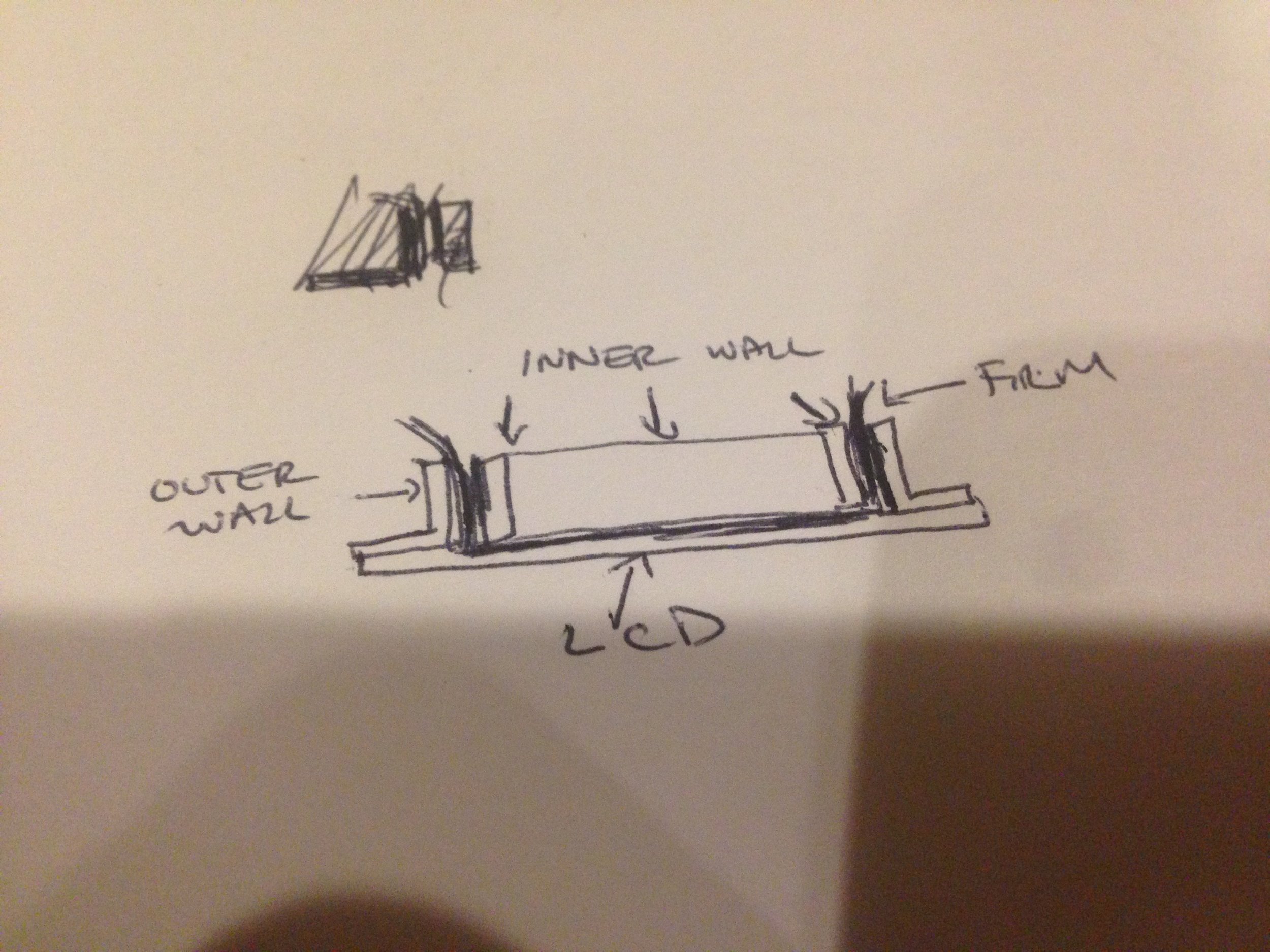

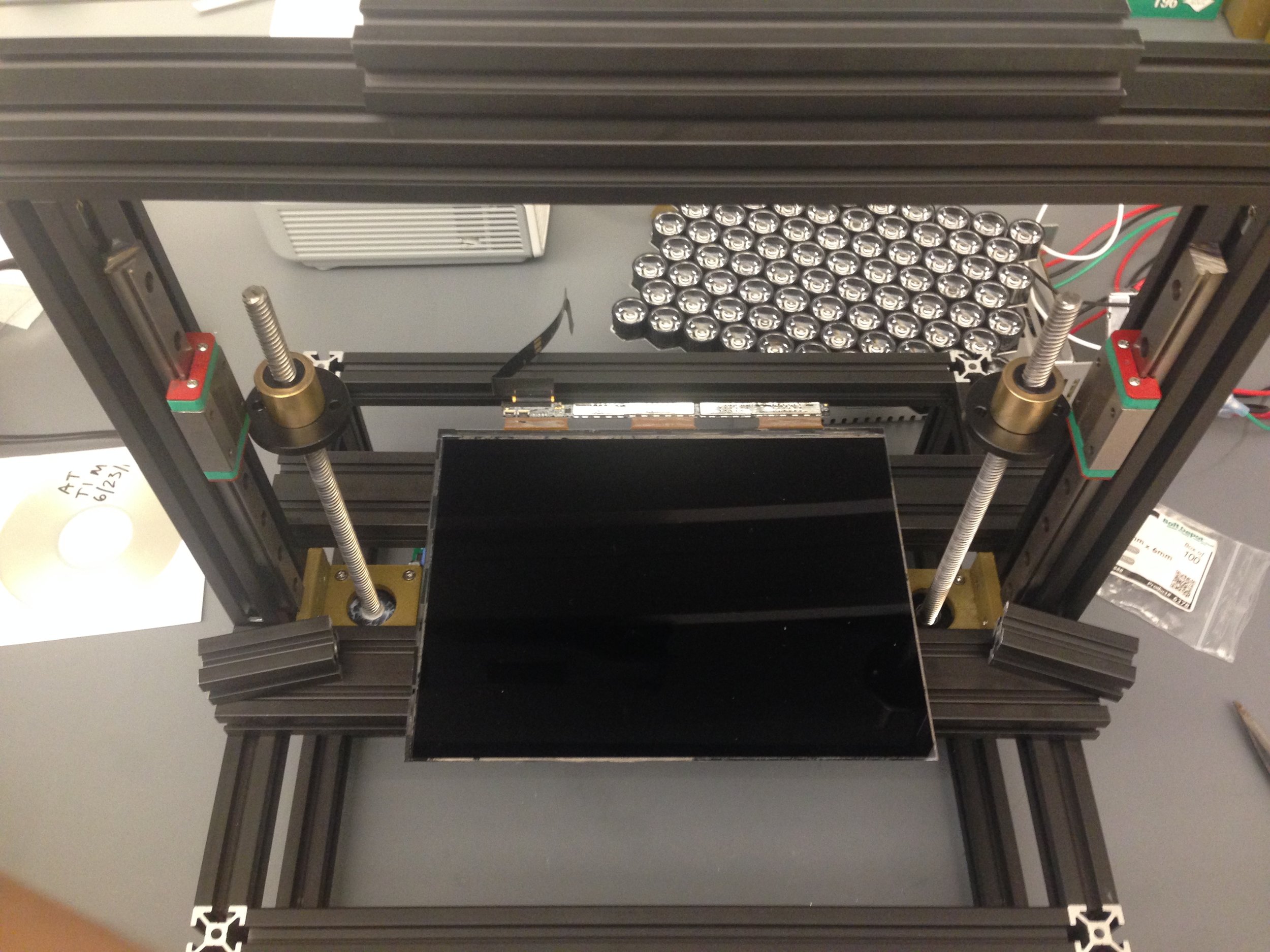

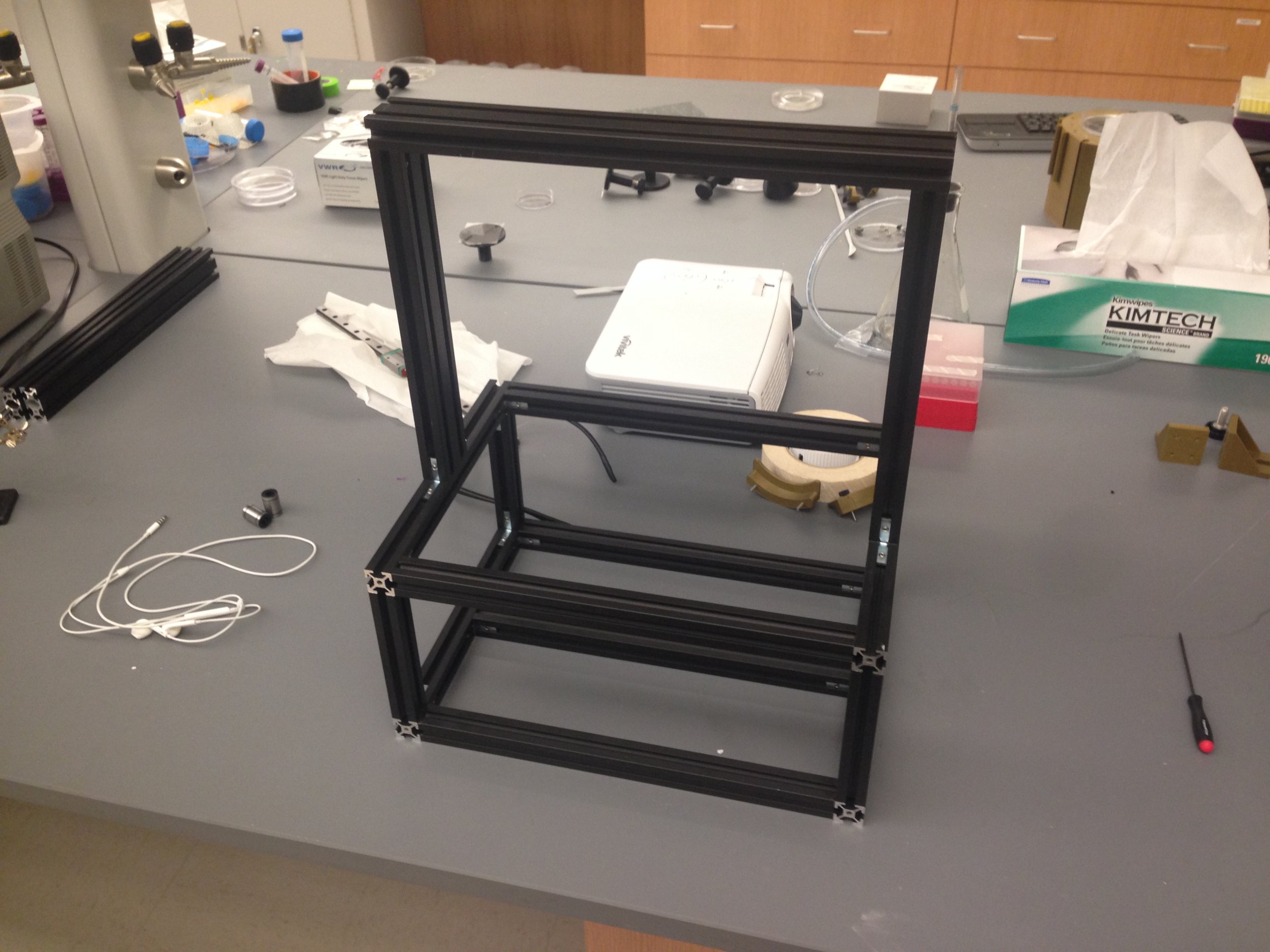

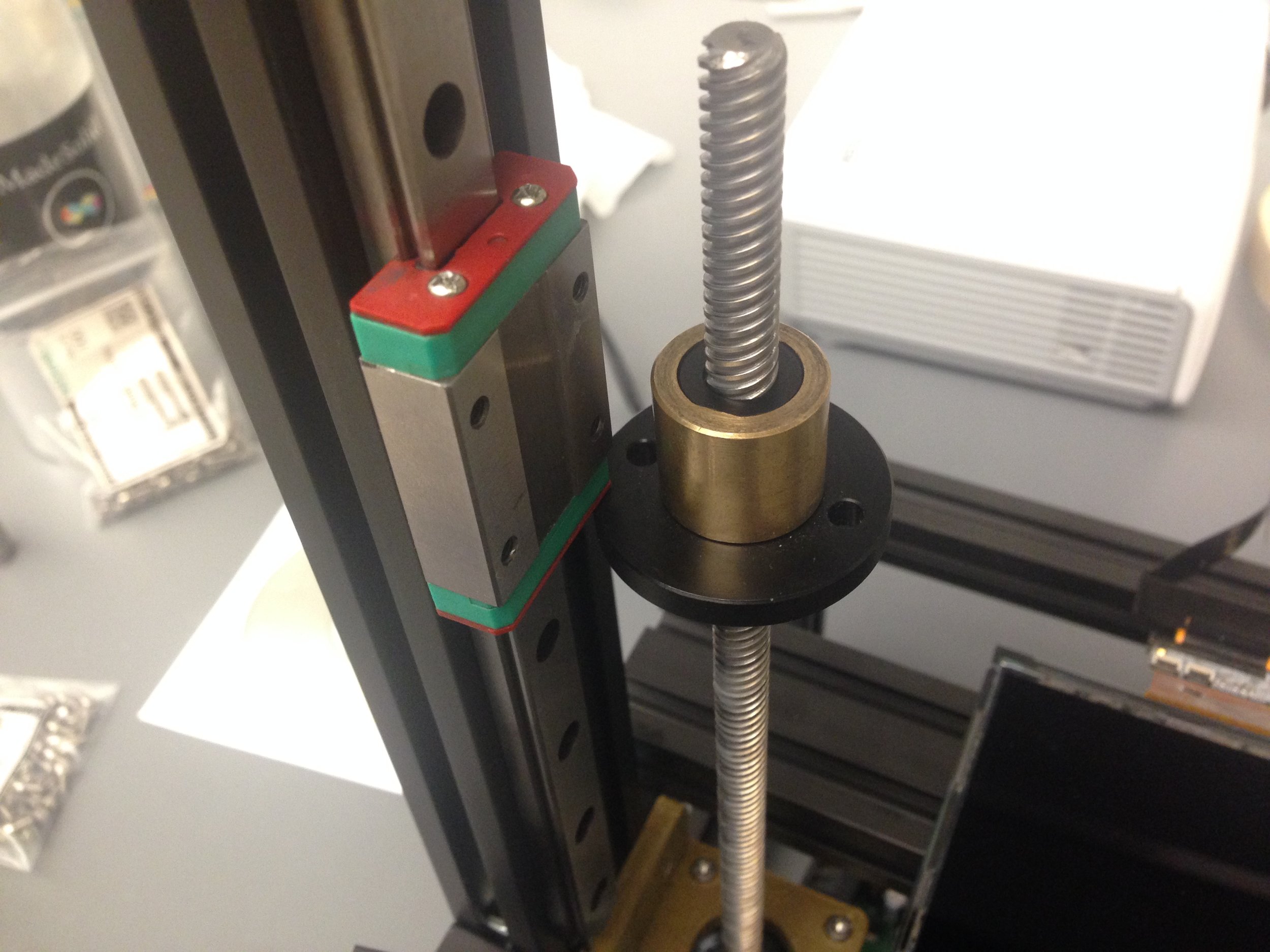

The overall concept of the machine design would be the same. We have the iPad screen as our projection area, reservoir/vat would sit ontop of it and Z axis would move the build platform up and down.

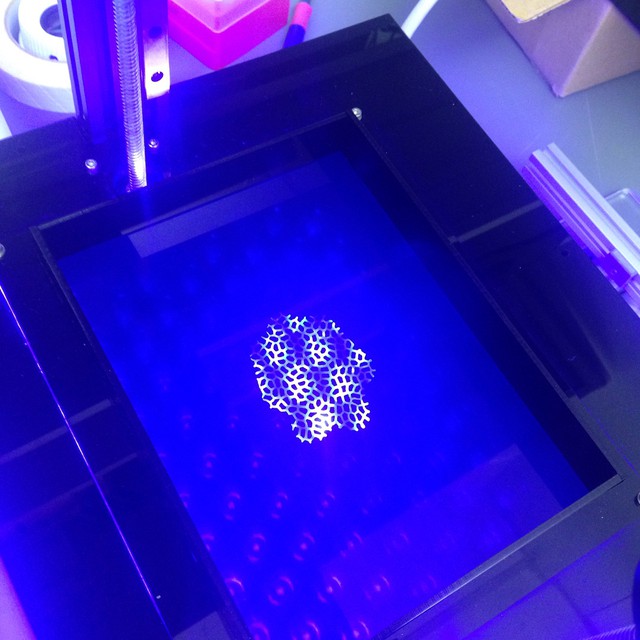

Using the iPad display, we got a much bigger build area at the loss a little bit of resolution. We went from 50 microns (0.05mm) to 96 microns (0.096mm ) XY resolution.

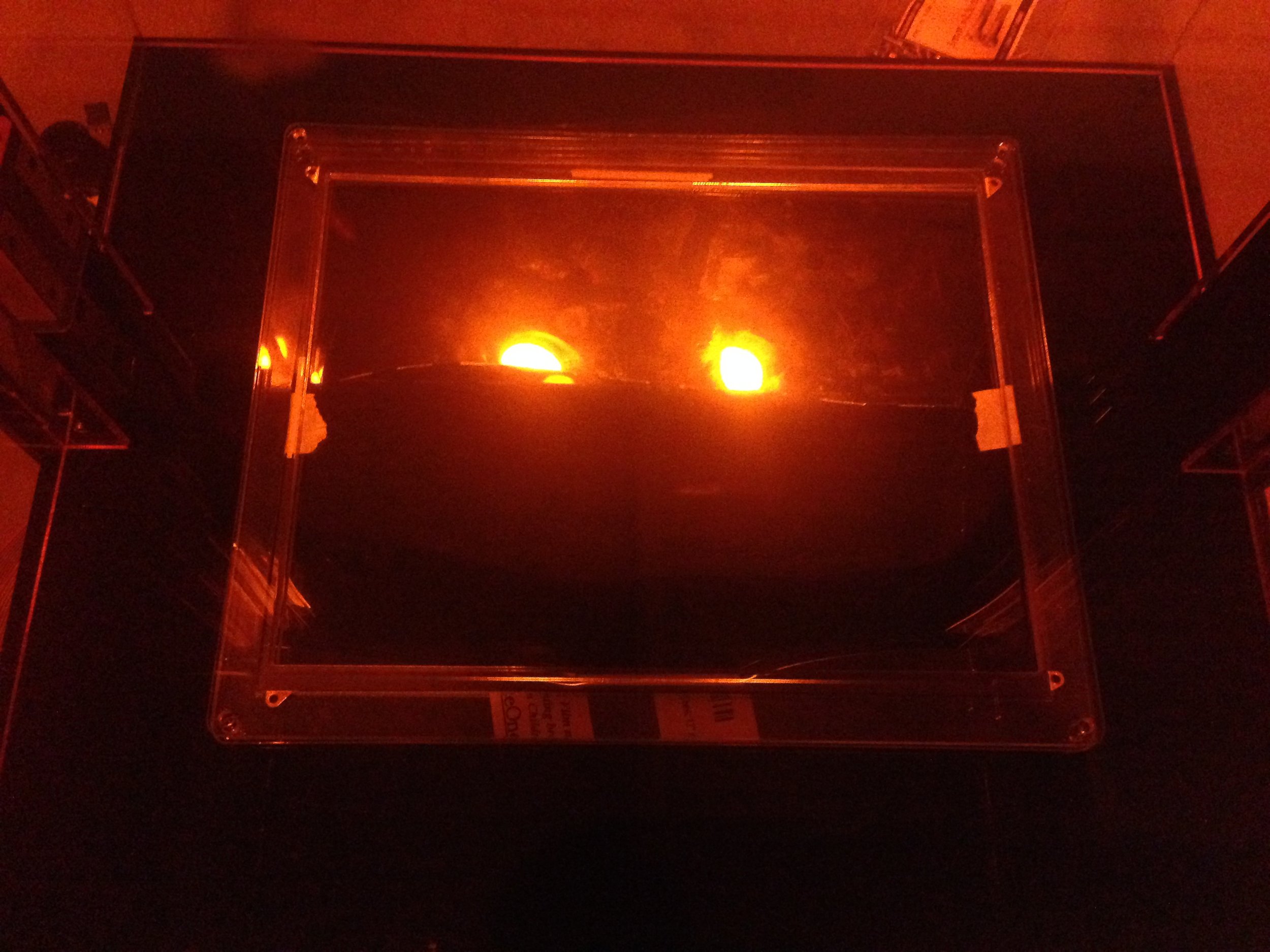

Last thing we had to address was the UV light source, the iPad screen backlight would not work. I'm pretty vocal and active in most of my projects in some capacity on the internet, at the time there was a central forum where a lot of individuals working on SLA technologies congregated...buildyourownsla.com. From there I was able to piggyback off of another efforts UV LED array.

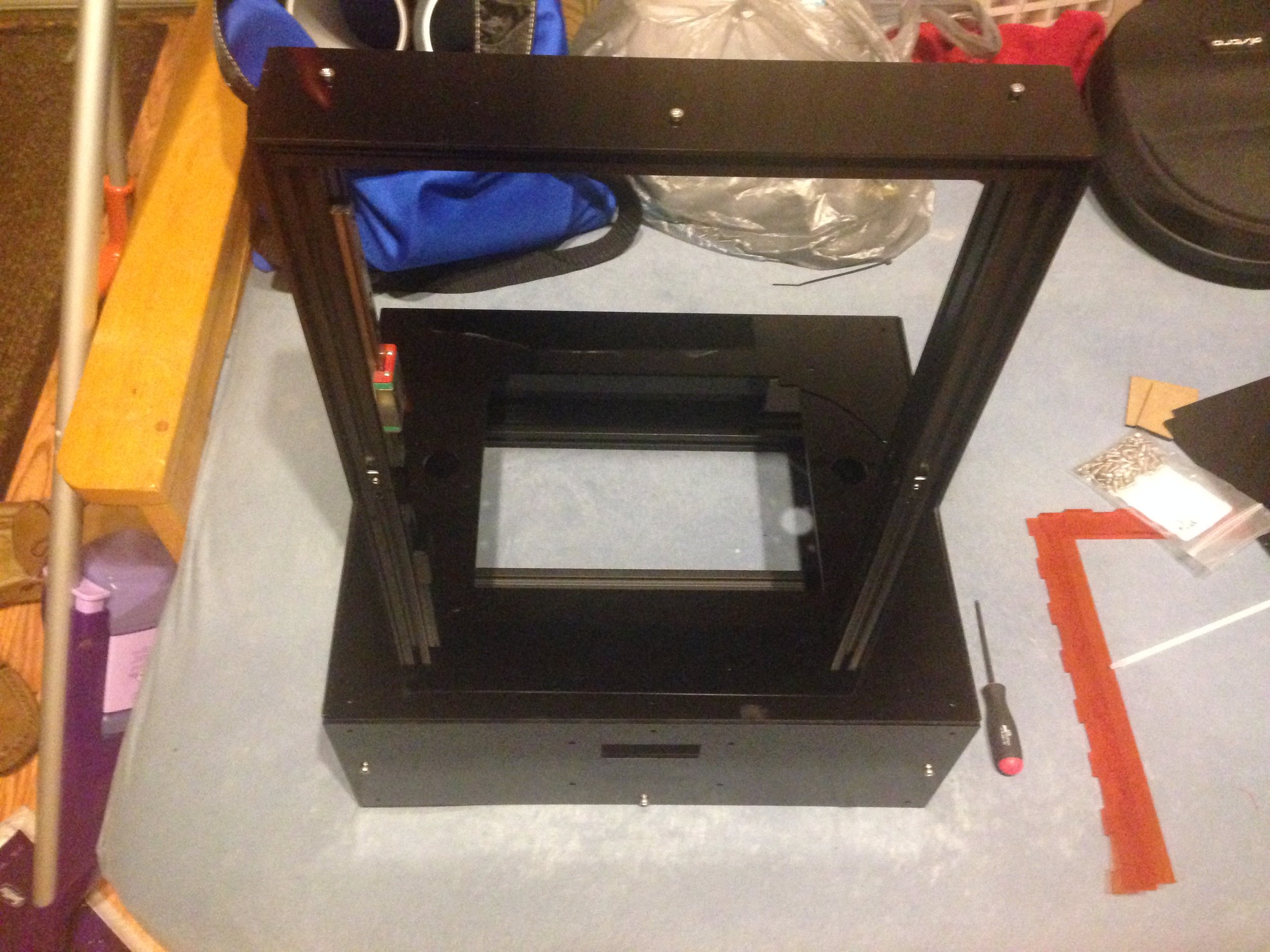

overview

Most of the SLA work I've done up until this point revolved around using a projector with UV content to print. As we were trying to scale the quantity of printers we'd use, we learned that the cost of projectors did not really drop off even in quantity. So we had to look at alternative patterning methods, this is when we came across an approach with LCD panels. Initial concepts we found were a monstrosity, lower resolution and involved some heavy modifications to the said LCD. It didn't look good but still worth investigating.

So cost of the projection mechanism was the driver in looking at a LCD based sstem, now if only there was an display that was high resolution, mass produced, and easy to source...hmmm? How about a replacement Reting iPad display?! I had been working with these displays previously to make portable secondary displays, so I knew where to get them and how to drive them too.

Future

I had to shelf this concept as things started to pick up with Open Factory business.

In the time since, a lot of other efforts have been made successfully at creating and LCD based SLA system. Today you can get your own machine off of AliExpress for a mere $615!

Issues

Though I was able to get some initial curing, there was a major issue with the iPad approach. The UV content was being dramatically weakened as it passed through the LCD and curing was taking a lot more time than we expected.

Each pixel of the display has an RGB filter, the light from the LED array was approximately 410nm. A little bit of it the light could pass through, but having multiple filters and polarizers, a lot of light was loss.